Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

Laser metal deposition is widely adopted for coating, reparation and 3D printing. Using COMSOL, we have developed a numerical model with full coupling of laminar fluid flow and heat transfer. The Marangoni effect is considered to capture the enhanced convective heat transfer as well as ... Per saperne di più

Autoliv Livbag is a company specialized in the development and manufacturing of gas generator for airbags based on pyrotechnic and compressed gas technologies. In this context, specifications of the product are very particular. Indeed, the gas generator needs to be airtight for several ... Per saperne di più

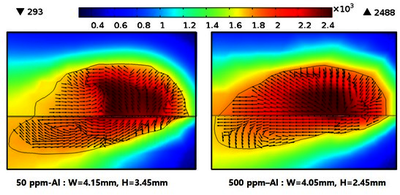

Marangoni flow affects the heat and mass transfer occurring in the molten metal regions in welding and additive manufacturing processes. It originates from the surface tension gradient (∂γ/∂T) induced at the melt pool surface due to the temperature difference. The flow pattern within ... Per saperne di più

Simulation of arc-wire additive manufacturing is under development in many academic and industrial sectors and at different scales. The study at the melt pool scale is often interesting to study deposition shapes and defects but not very relevant to calculate the stresses and strains at ... Per saperne di più

Induction brazing is a widely utilized joining process in various industries, offering efficient and localized heating for the assembly of diverse components. At Schneider Electric®, this process is used to assemble a silver piece on a copper piece. This work focuses on the advancements ... Per saperne di più

In the nuclear industry, and particularly at Framatome, mastery of welding processes is essential. Framatome is one of the world leaders in this field and wants to improve even more. The work presented focuses on improving the TIG (Tungsten Inert Gas) welding process, and more ... Per saperne di più

Introduction Numerical modeling of melt-casting is becoming a popular tool for the energetic materials and explosives industry. Compared to traditional metal casting, the cooling cycle for explosive melts is significantly longer because of their high Prandtl numbers [1]. Improving the ... Per saperne di più

Arc plasma can heat and melt the metal material and flows of molten metal can be affected by several forces such as Lorentz force which is ruled by current, Marangoni force controlled by surface tension, buoyancy force, and arc drag force. Usually, surface tension variation is determined ... Per saperne di più

Additive manufacturing gathers technologies where near net shape components are produced by depositing successive layers of materials. Among these technologies, the Layer Beam Melting (LBM) process – often referred to as Selective Laser Melting (SLM) – is garnering industrial interest, ... Per saperne di più

The Laser Metal Deposition process (LMD) is a rapid free form fabrication method which can be used to manufacture new near net shape metallic components, to repair used ones or to add functional parts on existing ones. This process is composed by multiple gas streams flowing inside a ... Per saperne di più