Scopri come la simulazione multifisica viene utilizzata per ricerca e sviluppo

In questa sezione troverete i lavori presentati alle Conferenze mondiali COMSOL. Le presentazioni descrivono ricerche e prodotti innovativi progettati con COMSOL Multiphysics da colleghi di tutto il mondo. I temi delle ricerche presentate abbracciano un'ampia gamma di settori produttivi e aree applicative, in ambito elettrico, meccanico, fluidodinamico e chimico. Lo strumento di Ricerca Rapida vi permetterà di trovare le presentazioni che si riferiscono all'area di vostro interesse.

Visualizza gli articoli presentati alla COMSOL Conference 2020

Additive manufacturing gathers technologies where near net shape components are produced by depositing successive layers of materials. Among these technologies, the Layer Beam Melting (LBM) process – often referred to as Selective Laser Melting (SLM) – is garnering industrial interest, ... Per saperne di più

Additive manufacturing technology is becoming more popular for the fabrication of metal products as it offers rapid prototyping and large design freedom. However, part quality of components fabricated by current additive manufacturing technology is not comparable to that produced by ... Per saperne di più

Additive manufacturing processes are increasingly used for designing metallic parts with complex geometries. The current needs are focused on the manufacturing of large-scale parts, typically of meter range. However, for such dimensions, the traditional trial-and-error methodology used ... Per saperne di più

Laser beam welding is a key technology in industrial manufacturing as it combines high flexibility and the potential for automation with excellent joint quality and minimal thermal influence of the workpiece. Whereas for materials like steel and aluminium laser beam welding is already ... Per saperne di più

COMSOL Multiphysics® is being utilized to develop Thermal Model for Wire Directed Energy Deposition Additive Manufacturing (Wire-DED) process with an objective to analyse the heat transfer phenomenon during and after the process. Wire-DED process’s growing industrial acceptance at a very ... Per saperne di più

A one-dimensional model of Excimer Laser-Annealing of amorphous silicon layers which are irradiated with a KrF excimer laser is described. For realisation, the application mode heat transfer in solids is used. The model predicts a melt threshold for the energy density of the laser of 88 ... Per saperne di più

The Finite Element Method (FEM) has become an established numerical tool used for different academic and industrial purposes. It allows the prediction of weld pool geometry, thermal cycle, final distortion and residual stress field during and after fusion welding. The capability of the ... Per saperne di più

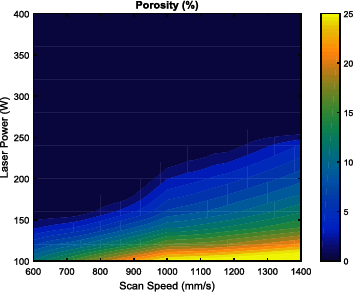

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal ... Per saperne di più

Additive manufacturing is attracting more and more interest. Laser Cladding is one of these additive manufacturing processes. For this a quasi-stationary physical based 3D process model is presented, which has been developed taking into account heat transfer, melt pool fluid flow ... Per saperne di più

Hybrid laser-MIG arc welding has very interesting advantages compared to laser welding or arc welding used separately. It is known that improvement of productivity results in higher welding speeds, thicker welded materials, joint fit-up allowance, better stability of molten pool, and ... Per saperne di più