Aggiornamenti Chemical Reaction Engineering Module

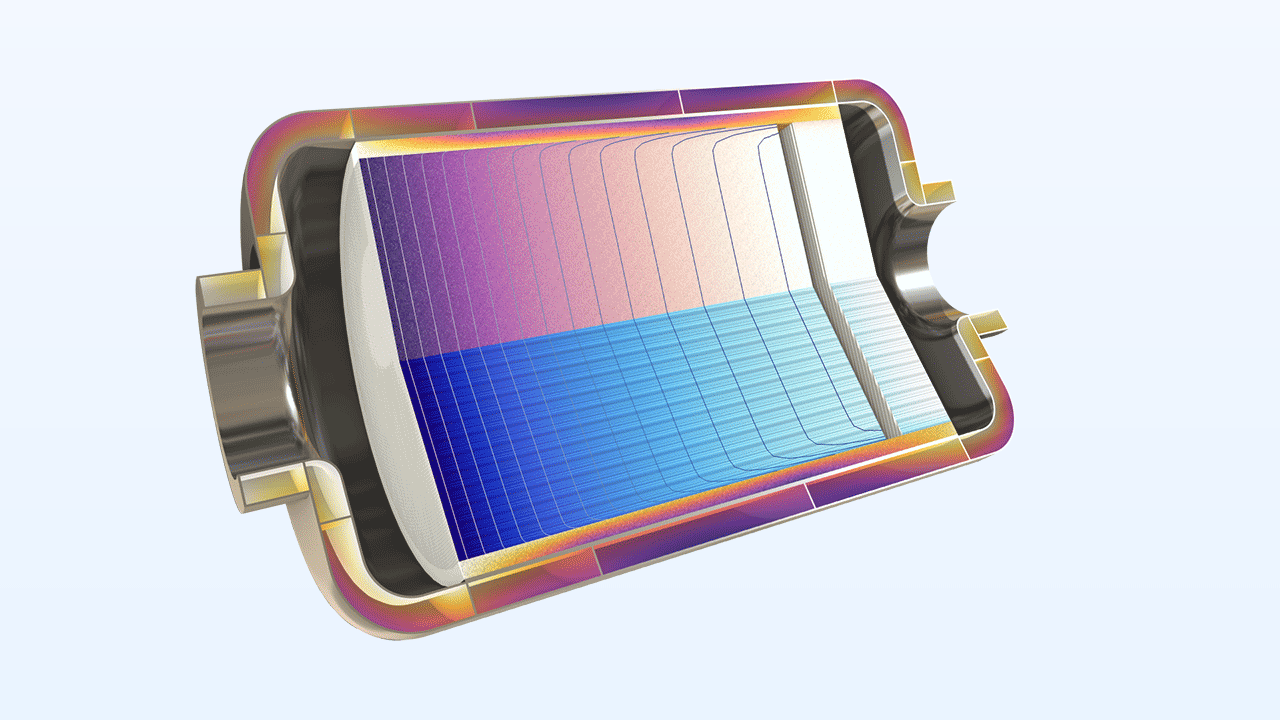

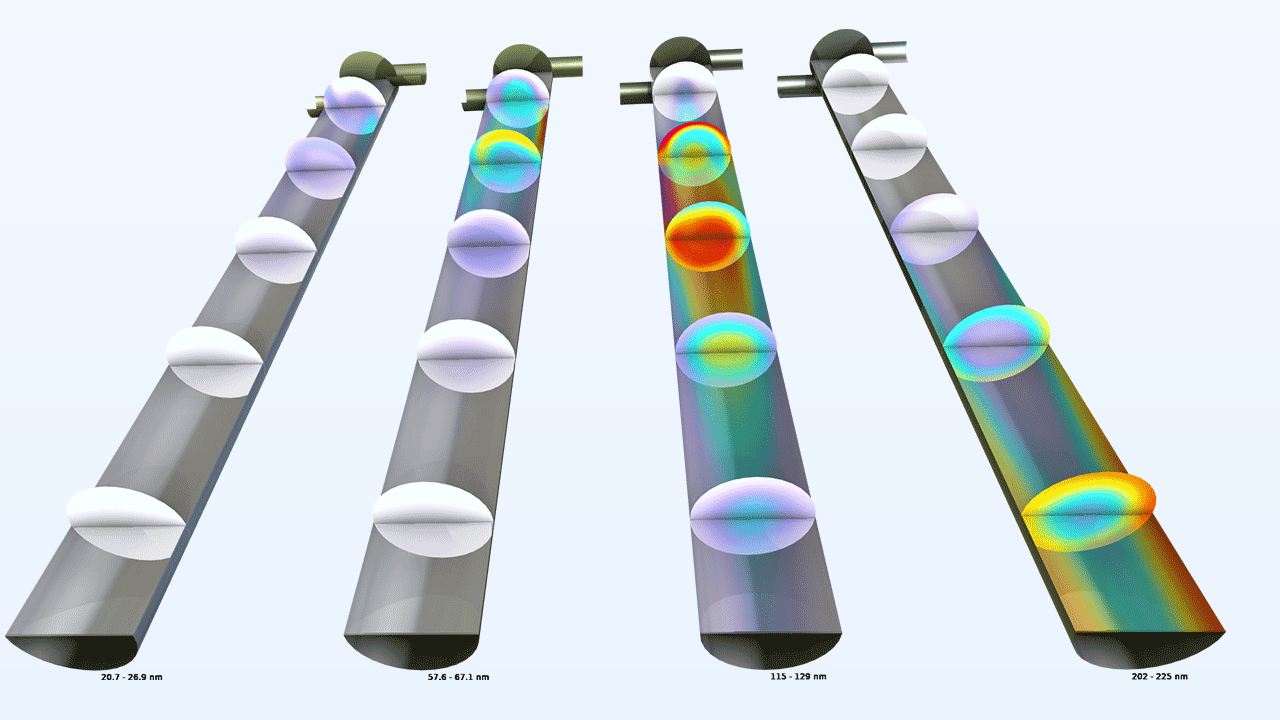

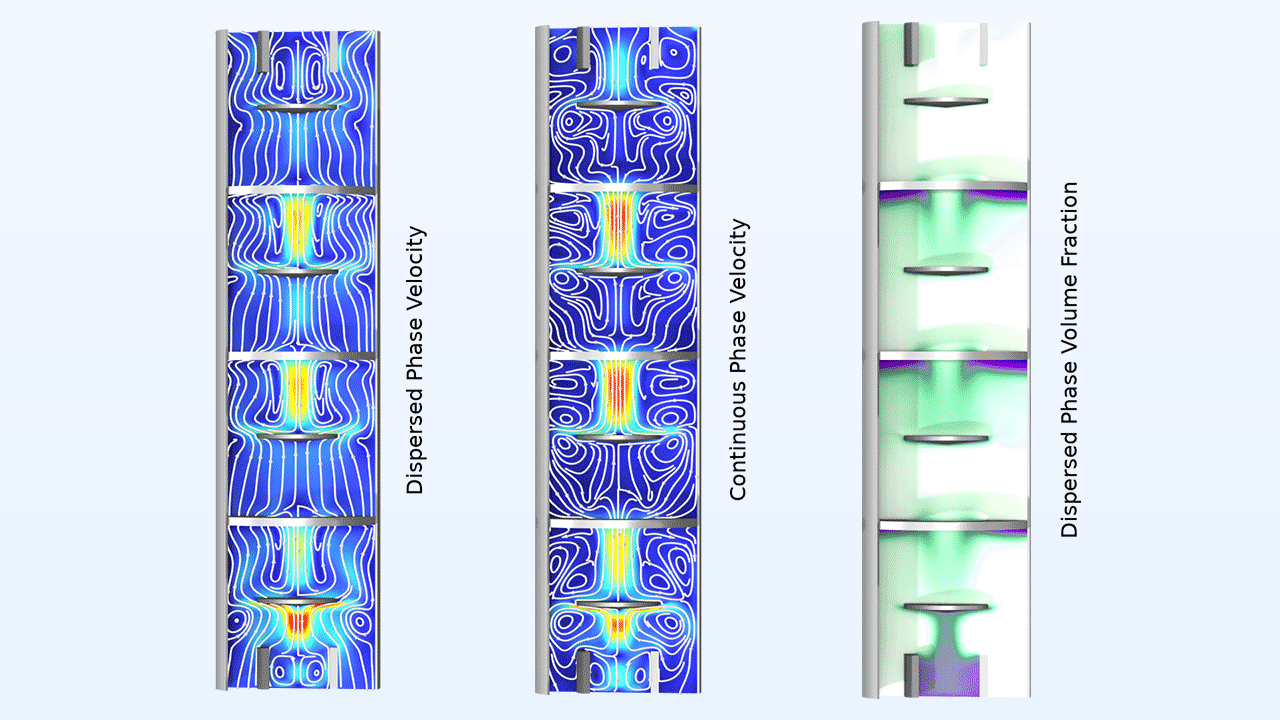

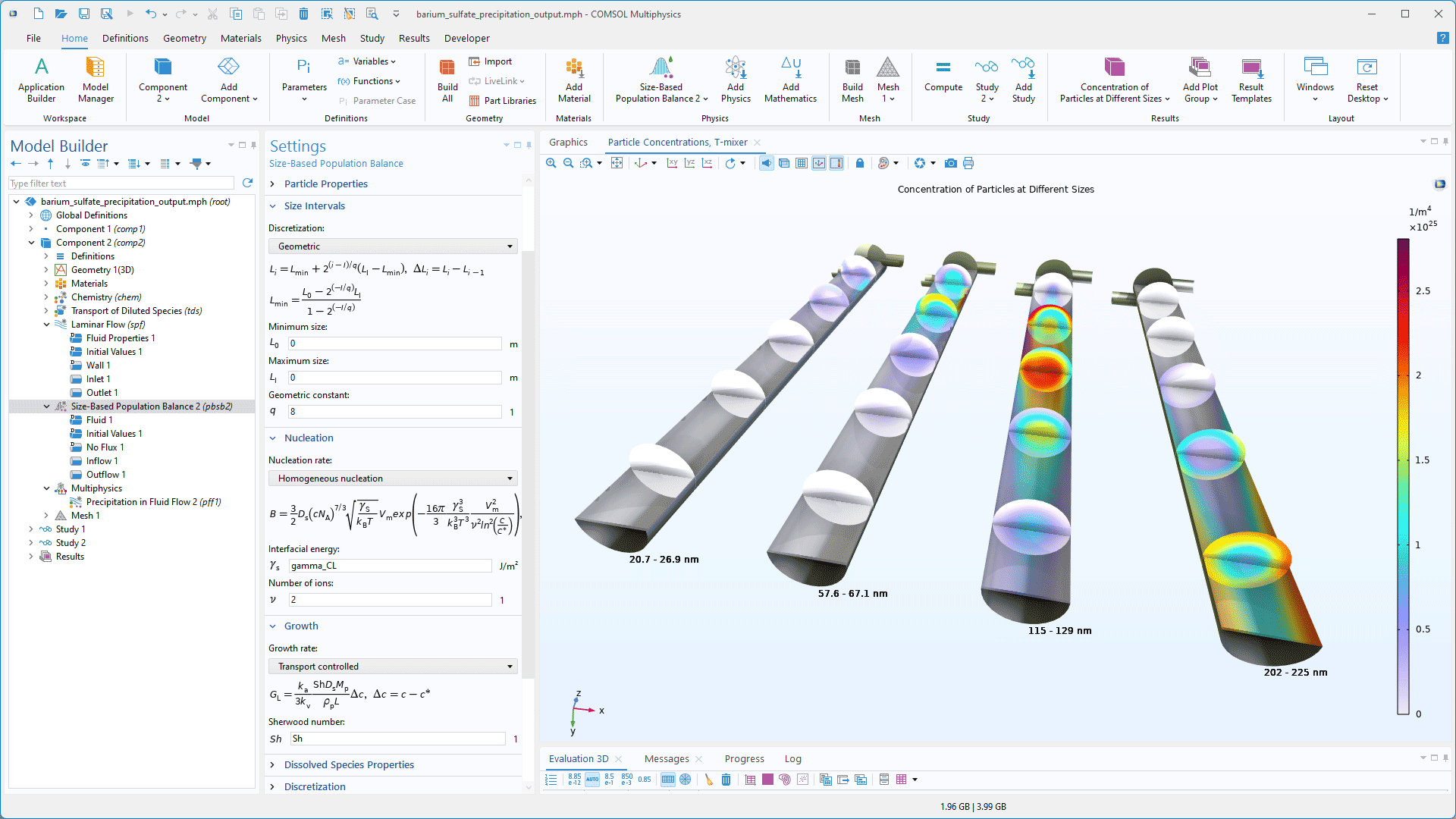

Precipitazione e cristallizzazione con il bilancio di popolazione

La nuova funzionalità per la modellazione dei processi di precipitazione e cristallizzazione consente di studiare i processi di separazione in settori quali la chimica fine, la chimica in massa e l'industria farmaceutica. In geometrie dipendenti dallo spazio, l'interfaccia Precipitation and Crystallization in Fluid Flow combina la nuova interfaccia Size-Based Population Balance con le interfacce Transport of Diluted Species e Laminar Flow. Calcola la distribuzione della popolazione nel tempo e nello spazio, ossia risolve la densità numerica di tutte le dimensioni delle particelle, tenendo conto della nucleazione, della crescita e del trasporto del fluido. L'interfaccia Precipitation and Crystallization in Fluid Flow può essere utilizzata anche per calcolare la distribuzione delle particelle in un modello di reattore ideale. Il tutorial Precipitation of Barium Sulfate dimostra questa nuova funzionalità.

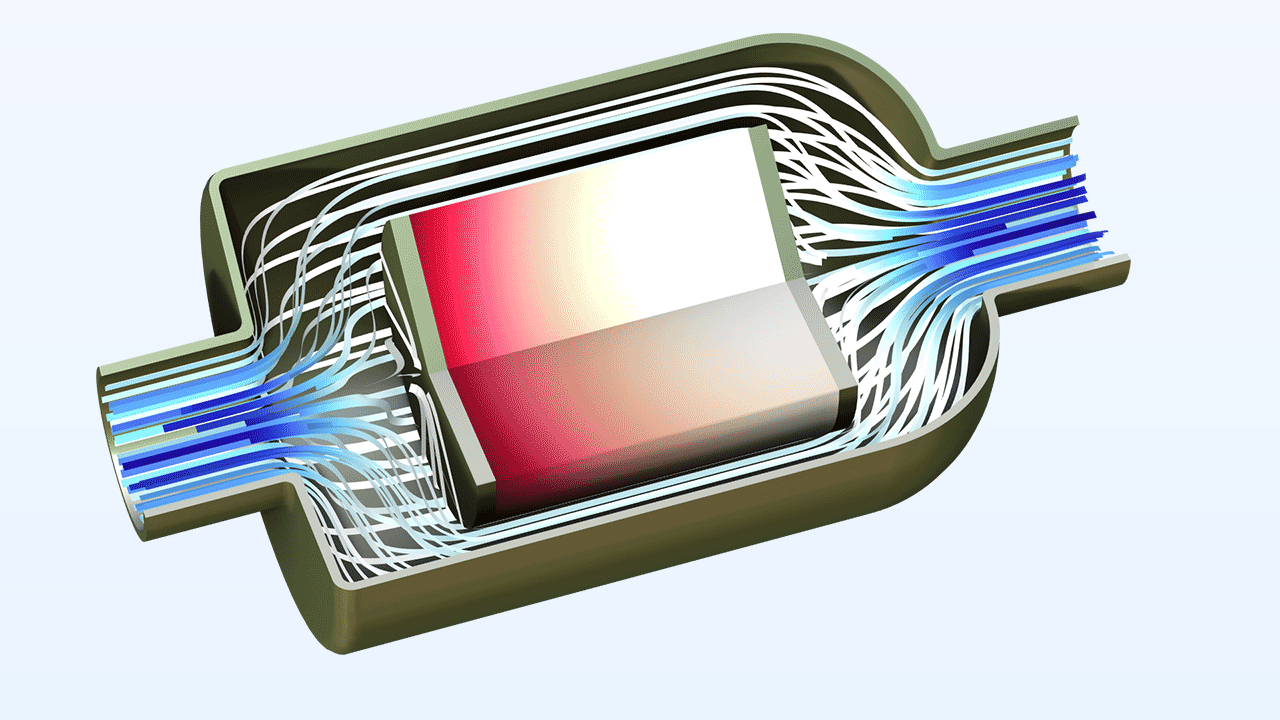

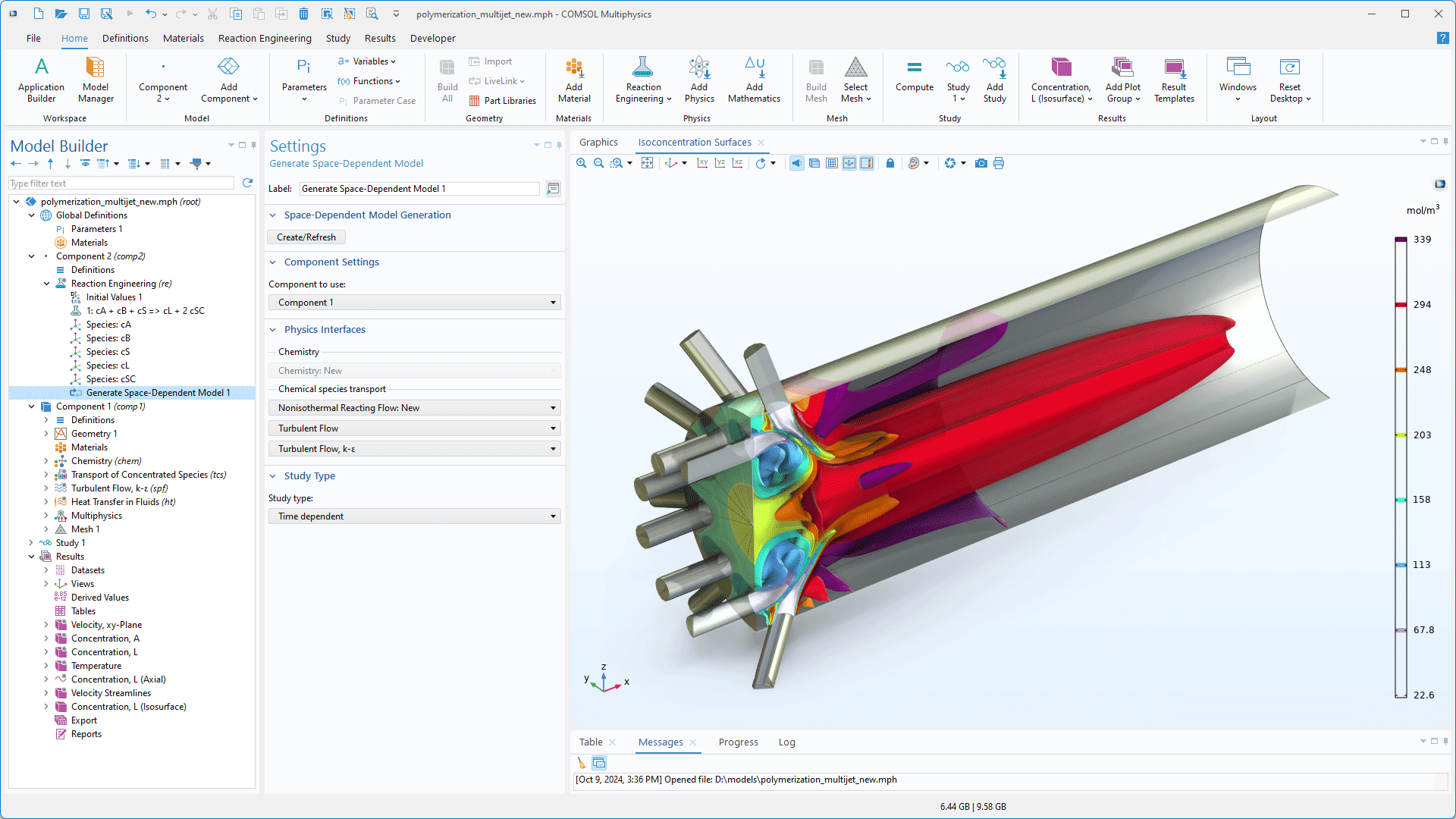

Generare modelli dipendenti dallo spazio per il flusso turbolento reattivo

La creazione di modelli di flusso turbolento reattivo dipendente dallo spazio è ora più semplice e supporta gli studi nelle scienze ambientali e in vari settori, tra cui quello chimico, farmaceutico e alimentare. La funzione Generate Space-Dependent Model formula automaticamente modelli di flusso turbolento isotermico e non isotermico direttamente dalle reazioni chimiche, eliminando la necessità di impostare manualmente la turbolenza. Accoppia i modelli di turbolenza Navier-Stokes mediati da Reynolds (RANS) con l'interfaccia Chemical Species Transport (e, per il flusso non isotermico, anche con l'interfaccia Heat Transfer in Fluids) e utilizza il modello di Kays-Crawford per default per il trasporto di massa e calore.

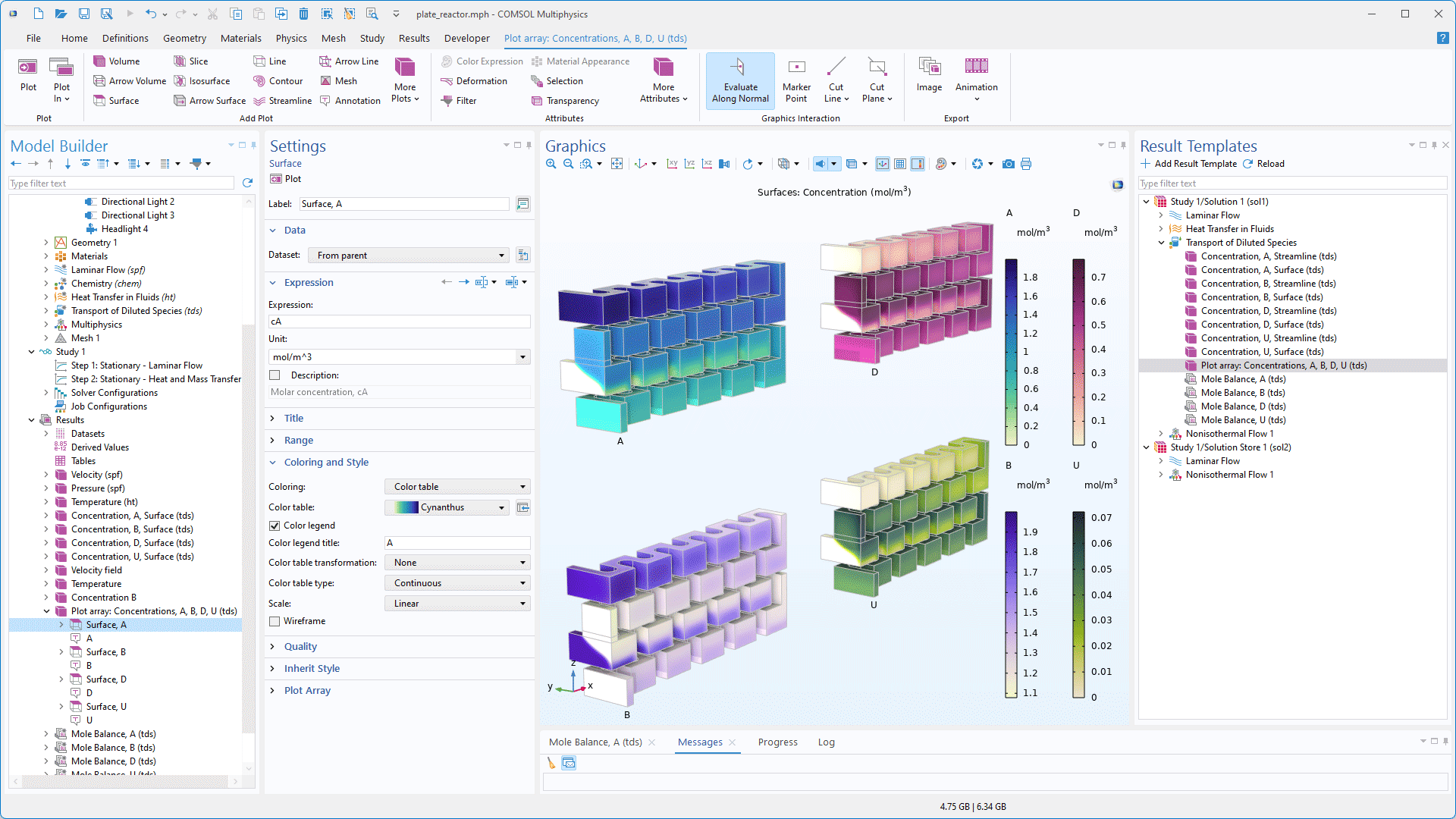

Modelli di risultato nelle interfacce di trasporto delle specie chimiche

La creazione di grafici utili e visivamente accattivanti di sistemi reagenti può richiedere molto tempo, poiché spesso ci sono molti reagenti e quindi molti campi di concentrazione da rappresentare. Per risparmiare tempo, nelle interfacce di Chemical Species Transport sono disponibili diversi nuovi Result Templates. Tra questi, sono ora disponibili modelli di matrice di grafici che includono fino a quattro concentrazioni di specie contemporaneamente nella finestra Graphics. I Result Templates sono disponibili per tutte le interfacce Chemical Species Transport, indipendentemente dal prodotto aggiuntivo, ma sono particolarmente utili per le interfacce di trasporto multicomponente incluse nei moduli per l'ingegneria chimica e nel CFD Module, nel Porous Media Flow Module, nel Subsurface Flow Module e nel Microfluidics Module.

Tutorial nuovi e aggiornati

La versione 6.3 di COMSOL Multiphysics® introduce diversi tutorial nuovi e aggiornati nel Chemical Reaction Engineering Module.