COMSOL News is now available in print and electronically, and you can request your copy of the multiphysics simulation magazine here. One of the great stories concerns a process engineer at Ruukki Metals in Finland, Mika Judin, who not only uses COMSOL to model and optimize his process, but lets the operators use the simulation too.

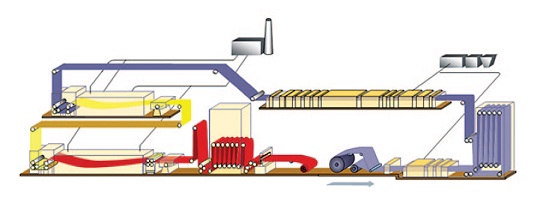

Ruukki Metals supplies metal-based components and systems to the construction and mechanical engineering industries. Coating these materials is an important part of this, and it’s important that the coating be applied evenly without discoloration. COMSOL models of the process therefore need to simulate the heat transfer and phase change that occurs during the drying process.

Mika’s analyses made it possible to fine-tune oven setups and provide feedback to paint manufacturers.

But the process is also very dependent on the operators and how they run their machines during different shifts, with different materials and coatings. Mika was able to give them a simplified interface to his COMSOL models that allowed them to simulate their process and fine-tune the operating process variables to provide the desired coatings.

It’s great to see how COMSOL customers apply their great modeling skills to boost productivity on the factory floor. Read more in COMSOL News 2012.

Comments (0)