Reducing the amount of plastic used in the production of bottled water would both help companies save on packaging costs and be more sustainable. That seems easy enough, until you consider the fact that during storage and transportation, the bottles are stacked on top of one another. With a lot of bottles comes a lot of mechanical load. How can companies reduce the amount of plastic without compromising the structure of the bottles?

3BL and Bottled Water

“Triple Bottom Line”, or 3BL as it is commonly referred to, suggests that today’s corporations need to not only worry about profit, but also consider the well-being of our planet and the people living on it. Sustainability practices are a part of this. Although bottling water in itself is not a sustainable practice, it is possible to enhance its sustainability by reducing the amount of plastic used in the packaging. Optimizing the thickness of the PET used for bottled water would further cut costs for bottling companies.

The structure of the plastic bottles fills more than one function: to contain water and support the weight of fellow bottles stacked on top. So what can those in the business of bottling water do to be in accordance with the notion of 3BL? As mentioned, the obvious answer is to optimize the packaging so that the least amount of plastic necessary to contain the water is used. But what about the mechanical load on the bottles as they are stacked?

Innovative Solution for Water Bottling Using PET

Researchers from DICAR, Politecnico di Bari, Italy sought to find out the answer to that question. They found that in order to minimize the thickness of the plastic bottles without compromising the structural integrity, they would need to add pressurized inert gas into the bottles. According to their paper “An Innovative Solution for Water Bottling Using PET”, the pressure of the gas will balance external loads to the extent where the packaging can be slimmed down.

The problem turned out to be of the highly nonlinear variety. The pressure of the gas depends on the volume and deformation of the bottle. While the bottle is deformed by external loads, the specific shape of the deformation depends on the pressure of the gas. Due to the nature of this water bottle problem, the researchers looked to multiphysics for a solution.

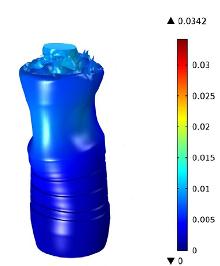

Deformed bottle of water without the pressurized gas. The displacements along the axis are shown. Image courtesy of: D. Scardigno, A. Castellano, P. Foti, A. Fraddosio, S. Marzano, M.D. Piccioni, of DICAR, Politecnico di Bari, Bari, Italy.

The research shows that adding pressurized gas to bottled water allows manufacturers to reduce the thickness of the PET while maintaining the stability of the bottle. That sounds to me like a good step toward improving the triple bottom line.

Get the full details of this water bottling research in the 2012 User Presentations resource.

Comments (0)