Veryst Engineering

Address & Contact Information

Veryst Engineering, LLC

47 Kearney Road

Needham, MA 02494

Phone: 781-433-0433

Fax: 781-433-0933

Email: multiphysics@veryst.com

Website: www.veryst.com

Veryst Engineering, LLC provides premium engineering consulting services. Driven by our mission — “Engineering through the fundamentals” — we use our grounded knowledge of mechanics, physics, materials science, manufacturing, and computational methods to produce practical and useful results that meet our clients’ needs.

We have experience using COMSOL Multiphysics® for companies and institutions across diverse industries, including biomedical, chemical, consumer products, energy, transportation, and manufacturing.

Areas of Simulation Expertise

Our consultants have expertise in numerous areas of multiphysics, including:

- Fluid-structure interaction

- Thermal-structure coupling

- Structural-acoustic interaction

- Electromagnetic heating

- Nonisothermal flows and conjugate heat transfer

- Electromagnetic-structural coupling

We also specialize in the following areas of physics:

- Fluid Flow

- Fluid mixing, multiphase flow, non-Newtonian fluids, film lubrication, microfluidic effects

- Structural Mechanics

- Polymer modeling, contact and impact, implementation of material models, shape memory materials, structural vibration, wave propagation

- Heat Transfer

- Conduction, convection, ambient radiation, internal (cavity) radiation, phase change

- Acoustics

- Acoustic tissue heating, pressure acoustics, acoustophoresis, aeroacoustics, linearized Navier-Stokes, thermoviscoacoustics, ray acoustics

- Species Transfer and Reactor Scaleup

- Drug delivery, diffusion (including through porous media), mixing in stirred tanks, packed bed reactors, bioreactors and processing of biological reagents, reaction kinetics and reacting flows

- Electromagnetics and Optics

- Electrostatics, magnetostatics, electrodynamics and electrical machines, RF and optical frequency simulations, ray tracing

- Particle Tracing

- Electromagnetic forces, fluid drag force, acoustophoresis, particle-particle interaction

- Microelectronics and MEMS

- Package thermal stresses and heating, design for reliability, stiction-based modeling, hybrid equation-based/finite element approaches for efficient modeling of electrostatic transducers

- Molecular Flows

- Isothermal and nonisothermal flows, multiple species, outgassing, adsorption, desorption, surface processes

- Semiconductor Devices

- Carrier drift/diffusion in larger devices, optoelectronics, quantum wells, wires and dots

Additional Services

In addition to computational simulation and analysis, Veryst provides services in the areas of material modeling, failure and root cause analysis, design, and manufacturing processes. Our expertise includes additive manufacturing, MEMS and sensors reliability, application (“app”) development, customized computational solutions, and chemical reactors and bioreactors.

Along with advanced polymer simulation, we have state-of-the-art, in-house testing facilities with custom test programs and fixtures, and can specify a test program that will capture your material’s response for use with a particular material model in COMSOL Multiphysics.

Veryst also develops PolyUMod®, a library of advanced user-material models that interface with COMSOL Multiphysics® and other FEA solvers, and enables more accurate predictions of constitutive behavior compared to standard material models. Veryst also develops the MCalibration® software, a tool that can calibrate all COMSOL Multiphysics® material models quickly and easily.

Featured COMSOL Multiphysics® Projects

The following are some examples of our work using COMSOL Multiphysics:

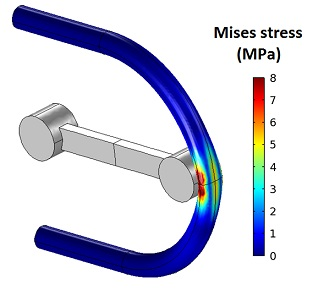

Fluid-Structure Interaction — Modeling a Heart Valve

Proper functioning of heart valves keeps blood flowing in one direction through the heart, and low stresses on the heart valves. Veryst modeled the way in which a heart valve opens and closes in response to fluid flow, providing insight that can be used to improve the design of artificial heart valves.

Axisymmetric heart valve model showing fluid velocity and von Mises stresses.

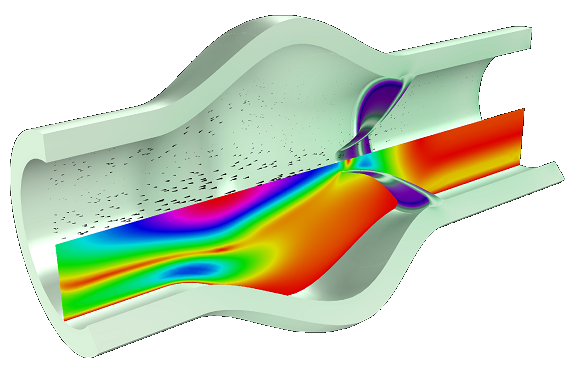

Electromagnetic Heating — RF Tissue Ablation

Veryst developed a COMSOL Multiphysics model of an RF ablation problem involving a monopolar electrode targeting a tissue close to a blood vessel. We accounted for the electric and heat transfer fields in the tissue and blood as well as the blood flow. We also predicted the temperature variation and the damage evolution in the tissue.

Temperature in the tissue and blood and flow streamlines in the blood.

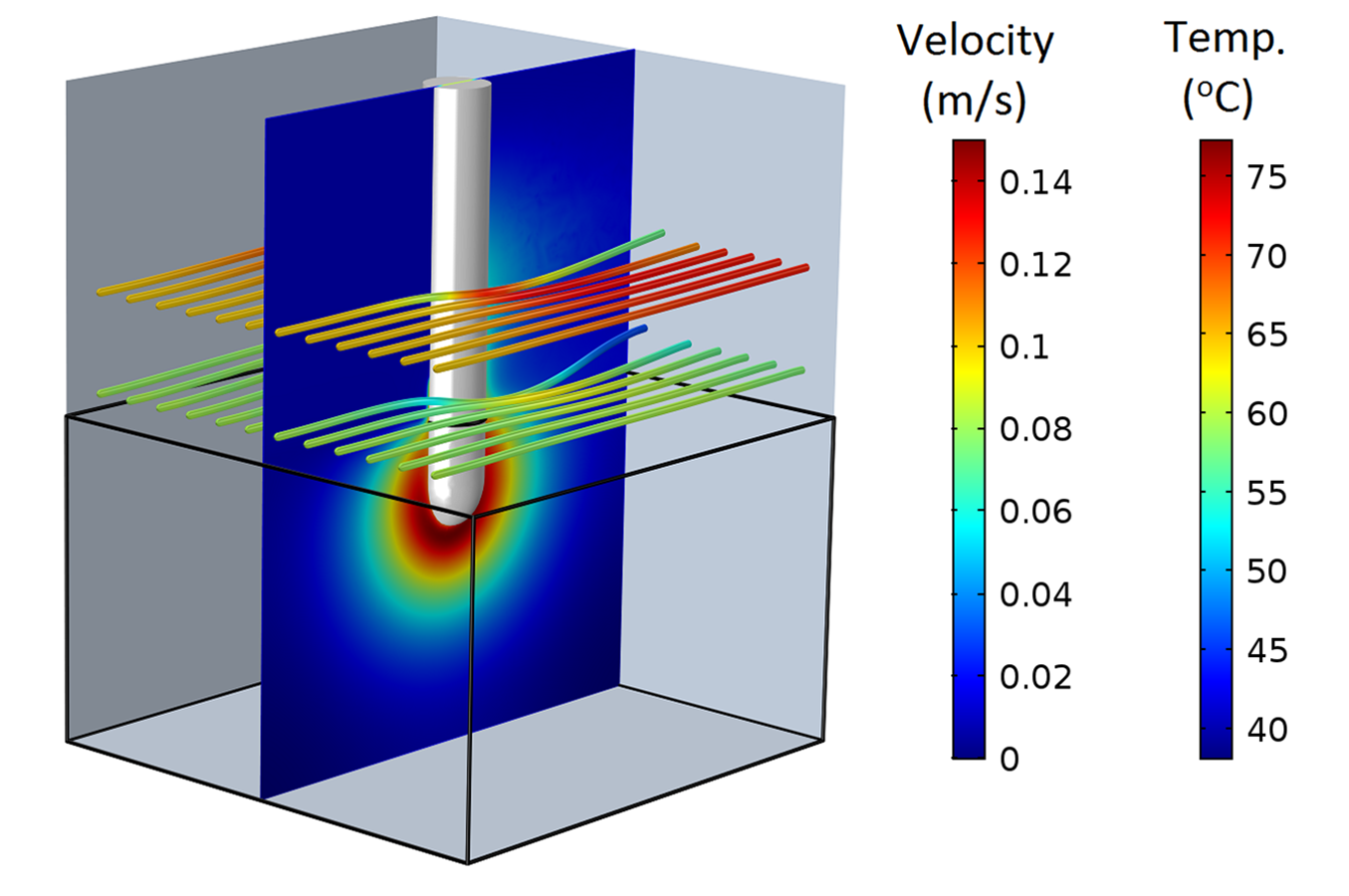

Reaction Kinetics — Scaleup in Chemical Reactors

Veryst assists clients with scaleup analysis of chemical reactors, from lab scale to pilot scale to production scale. The scaleup analysis requires detailed understanding of the underlying physics: reaction kinetics, heat transfer, mass transfer, and fluid flow. For example, the applicable mixing model and the laminar/turbulent flow characteristics may be quite different at the different scales.

Flow velocity in a baffled reactor stirred by a rotating impeller.

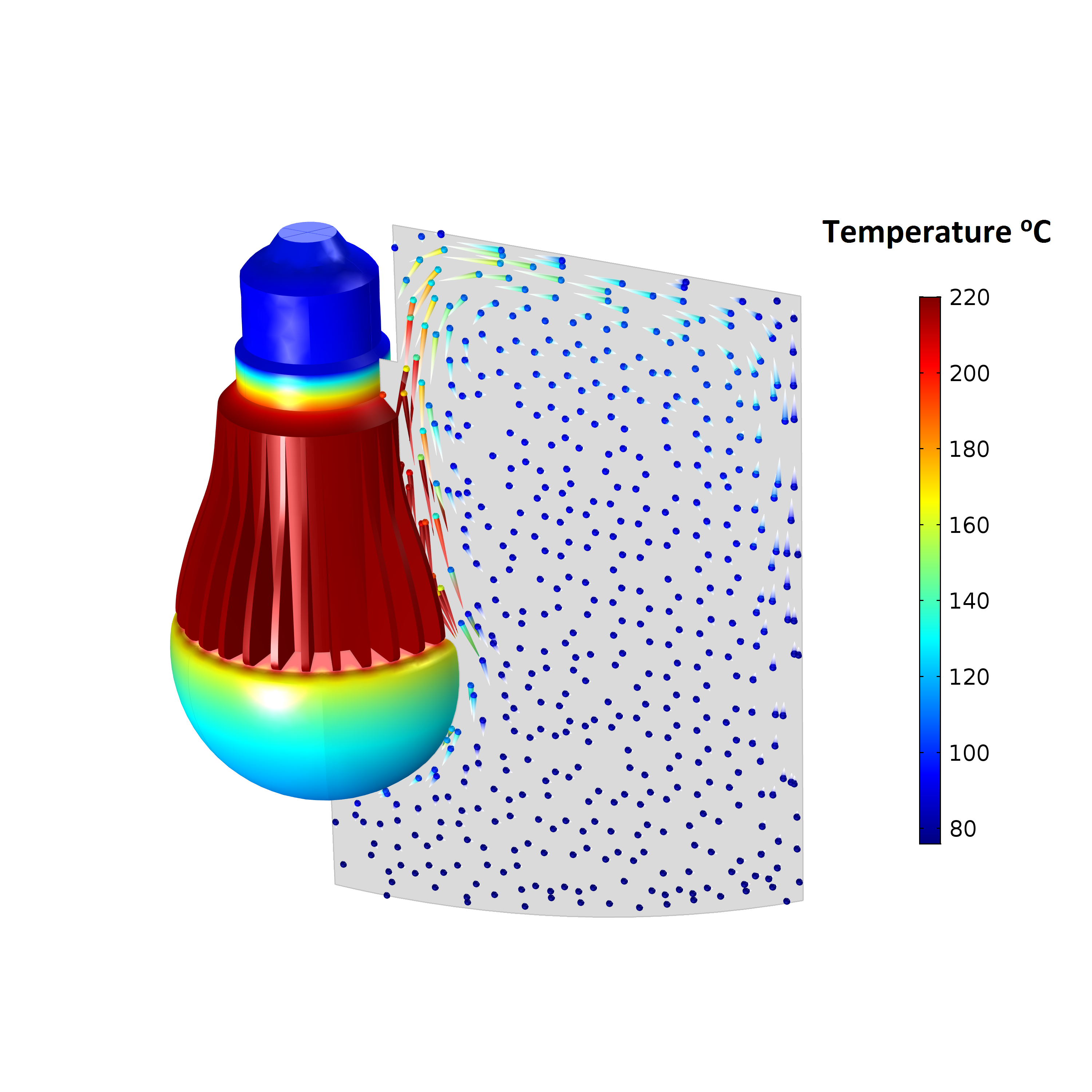

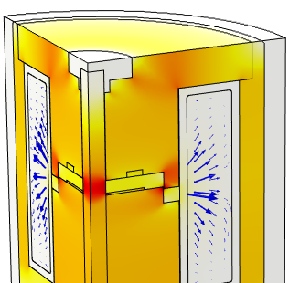

Nonisothermal Flows — Natural Convection Around LED Light Bulb

Veryst developed a conjugate heat transfer finite element model of an LED bulb and surrounding air in an enclosed recessed lighting fixture. Conduction between the LEDs and the bulb body, natural convection in the surrounding air, and radiation between surfaces were included to predict accurately the temperature of the LEDs.

Temperature variation and airflow due to natural convection around an LED bulb.

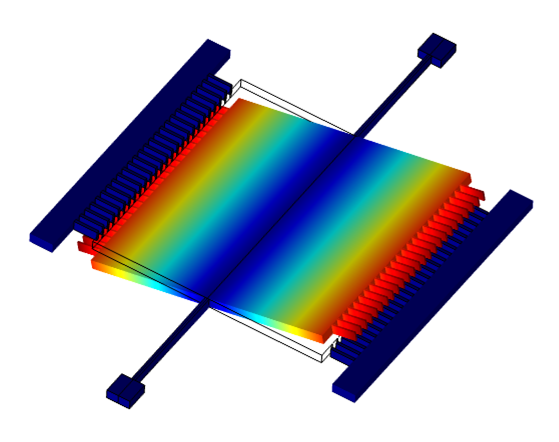

MEMS Modeling — Electrostatic MEMS Mirror

Veryst assists clients with design, simulation, fabrication, reliability, and failure analysis of MEMS devices. The simulation of MEMS devices usually involves coupling of several physics fields including electrostatics, heat transfer, structural mechanics, acoustics, and fluid mechanics. In this MEMS electrostatic mirror example we evaluate the main natural frequencies, the capacitance, and the mirror’s moment-angle relationship.

First mode shape of MEMS mirror at ~3700 Hz.

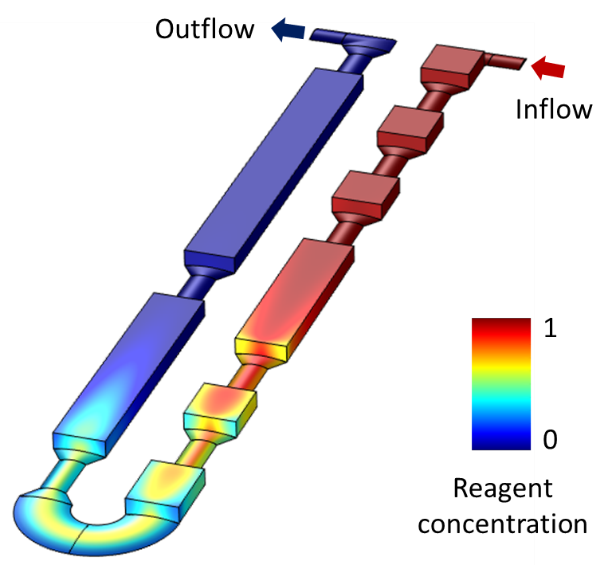

Microfluidics — Flow and Chemical Transport in a Diagnostic Device

Microfluidic lab-on-chip devices are revolutionizing biotechnology due to their low reagent volumes and rapid reaction times. However, handling fluid at the microscale demands a completely different way of thinking, since fluid behavior is often highly dependent on viscosity, boundary geometry, surface energy, and surface tension. We developed a coupled CFD species transfer model of the fluid flow and chemical transport within the channels and chambers in the device in the COMSOL® software. Optimizing the on-chip pumping sequence led to reduced reaction times, thereby accelerating device development and reducing prototyping and lab costs.

Flow and transport in a microdevice for diagnostic and genomic applications.

Electromagnetic-Structural Coupling — Analysis of a Solenoid Actuator

Our team developed an electromagnetic analysis of a defective solenoid and evaluated the forces on the structure and the resulting structural deformation.

Stresses and electromagnetic forces on solenoid actuator.

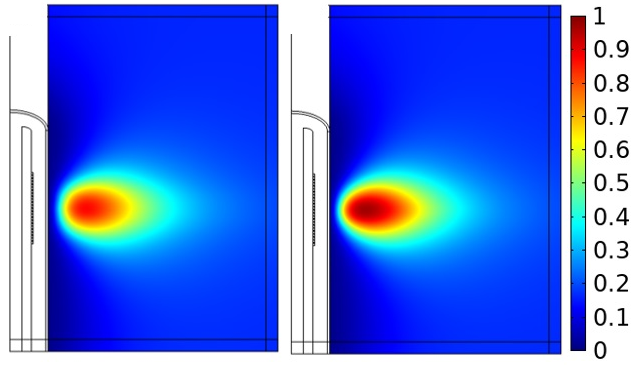

Structural-Acoustic Interaction — Acoustic Ablation Device

Veryst modeled a catheter-based acoustic ablation device with an array of piezoelectric acoustic transducers that induce tissue necrosis using an acoustic heat source. Model accounts for bioheat transfer and thermal tissue damage.

Fraction of damaged tissue after ablation for two electrode design variations.

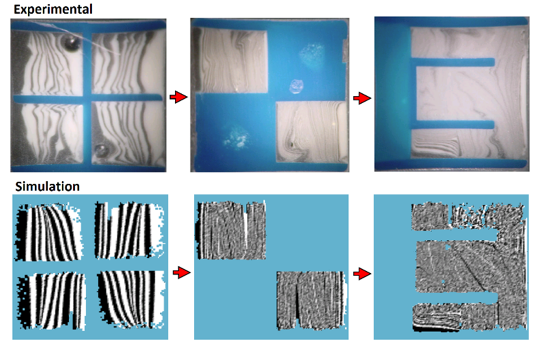

Non-Newtonian Fluid Flow and Particle Tracing — Laminar Static Mixer Analysis

We developed a new modeling tool for analyzing laminar static mixers that involves CFD analysis, particle tracing, and a novel mixing analysis algorithm. We applied an extensive grid of particles to evaluate mixing efficiency with very little numerical diffusion.

Mixing efficiency at different sections of static mixer showing good agreement between simulation and experiment.

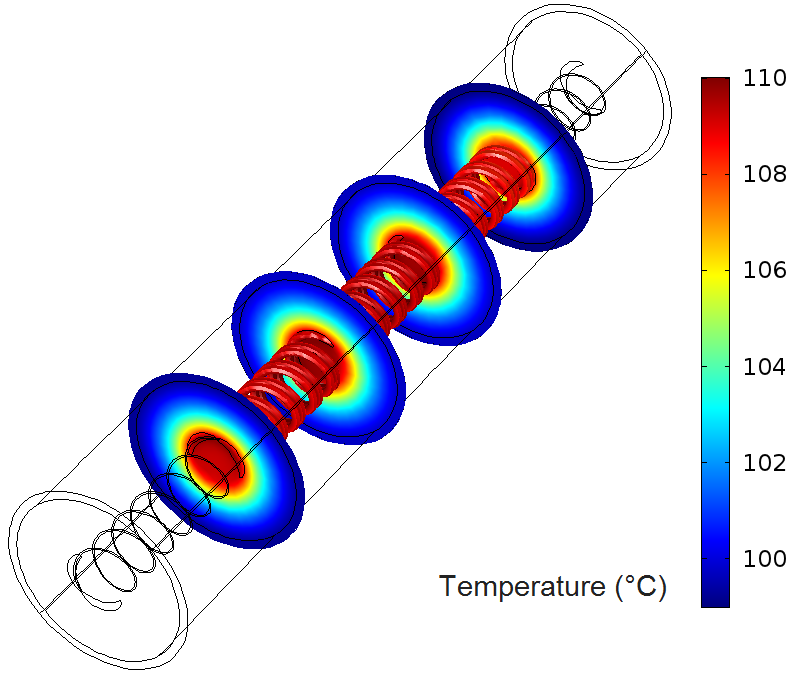

Thermal-Structural Coupling — Calrod Thermal Analysis

Veryst developed a thermal-electric-structural-coupled model of a Calrod composed of a heating wire, surrounded by a magnesium oxide insulation, and encased in a stainless steel tube. The model accounts for Joule heating and heat transfer within the Calrod through conduction and radiation.

Temperature variation in a Calrod at low applied voltage.