BI Dry 3.0 - A COMSOL App for Simulating Concrete Drying

Curing concrete is best achieved by keeping it nearly saturated at an appropriate temperature until all the cement has fully reacted. However, when installing flooring materials that require low relative humidity (RH) in the concrete, the slab needs to dry as quickly as possible. Concrete drying can be slow, often conflicting with construction schedules. This can lead to floors being installed before the concrete's RH is low enough, resulting in costly testing, legal disputes, and repairs.

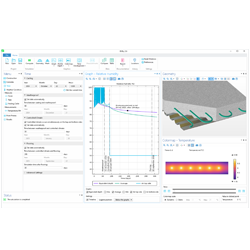

One effective approach for predicting concrete drying involves using finite element-based simulations. The BI Dry software simulates the drying process in concrete structures, helping contractors make informed decisions about concrete mixes and achieve desired relative humidity levels within required timeframes.

In 2022, Heidelberg Materials released HETT22 [1], a software to simulate the early-age temperature and strength development of concrete. It is entirely based on COMSOL Multiphysics® and compiled as a standalone executable using the COMSOL Compiler™. Given the success of HETT22, BI Dry 3.0 has been completely rebuilt on the same platform. Although there are many similarities between the two software applications, the timescale for concrete drying spans months or years, unlike the hours or days needed for strength development. Both BI Dry and HETT22 use the Maturity Method and the heat transfer equation, but BI Dry also solves a convection-diffusion equation for moisture content, coupled with heat transfer.

BI Dry contains a set of predefined slab structure cases, including concrete slabs on grade, slabs cast on different formwork, and top layer applications on existing concrete slabs. While all computations are performed in 2D, some visualizations utilize 3D. Users start by selecting the type of concrete and specifying the requirements. They then define the construction schedule, beginning with casting the concrete in an outdoor environment, followed by moving to a building with an assembled envelope and controlled temperature and humidity, and finally to the time of flooring. Weather conditions (temperature, wind, RH) are sourced from the ASHRAE 2021 database included in the Heat Transfer Module. Users specify the latitude and longitude, and BI Dry automatically finds the nearest weather station and assigns the appropriate boundary conditions. For castings in Sweden, precipitation data averages from 1991-2020 provided by the Swedish Meteorological and Hydrological Institute (SMHI) are used. Additionally, users can manually enter input data or directly import sensor data from the construction site. Once computed, several visualization options for RH and temperature versus time are available. Graphs and information windows clearly indicate whether the construction is dry enough or if further actions are needed to meet the requirements. It is also easy to compare different results, enabling users to find the optimal concrete mix and design.

BI Dry 3.0 features an intuitive graphical user interface, allowing contractors to perform advanced simulations without needing a background in mathematics or physics. Scheduled for release in fall 2024, BI Dry 3.0 will be available for free.

Download

- ericsson_9471_poster.pdf - 1.11MB

- 2_daniel_ericsson.pdf - 3.79MB