Induction Heating Modelling for Reheating Steel Blooms

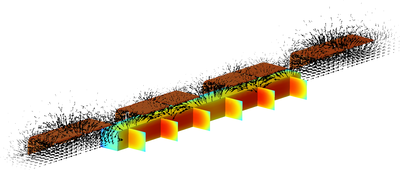

For reheating steel slabs in the steel industry fossil energy like natural gas or oil-based fuels is commonly used. Induction heating is one possible way on the transition towards a carbon free steel industry. To support the industries ambition to change from furnaces with fossil energy towards alternative heating furnaces modelling and simulation has an important role in decision making and design of new steel process plants. In this article a method to use the COMSOL Multiphysics® software to simulate the reheating of three different steel grades is presented. The modelling results are compared and validated against pilot trials of each steel grade performed at Swerims pilot facility in Luleå. The three evaluated steel grades are one low-alloyed ferritic carbon steel, one austenitic steel and one stainless steel (mixed austenitic-ferritic). The blooms were quadrangular with cross section of 290x125 mm and a length of 1700mm for the carbon and stainless steel and a cross section of 120x120 mm for the austenitic steel. The validation experiments were conducted at the pilot facility in Luleå using a 900kW induction heater with 4 coils. The blooms were heated using a frequency of 350 Hz from room-temperature to 1200 degree Celsius in the centre of the bloom. The temperature was measured during the experiments using five thermocouples at different positions inside the bloom. The temperature history, the electrical power input and the cooling losses were later used for validating the modelling results. A model of the pilot induction furnace was set-up using COMSOL Multiphysics® in which the full resonant circuit of the furnace was modelled using a coupled electrical circuit. The coils of the furnace were modelled using the numeric multi-turn coil feature to make it possible to mesh a quarter symmetry of the furnace using only 250 000 elements, making the model relatively computationally lightweight. Movement of the billet through the coils were modelled with a deforming mesh, while the induction heating itself was modelled using the Multiphysics interface “Electromagnetic Heating” to couple the magnetic fields and temperature in the blooms. The electromagnetic heating was modelled using a simplified approach in which only the effects of eddy-currents were considered, and the hysteresis of the material was ignored. The results show that the reheating process of steel blooms using induction can be modelled by COMSOL Multiphysics®. Comparison with experimental results from Swerims pilot plant show reasonable agreement even when using a simplified model. This first model shows that with some further development and modifications, COMSOL Multiphysics® can be very useful for modelling existing and future reheating processes in order to support the industry in the transition from carbon based reheating furnaces to electrical heating furnaces and therefore contribute towards a fossil-free steel industry.