Using Artificial Intelligence (AI) within COMSOL Multiphysics to Create Machine Learning Tools

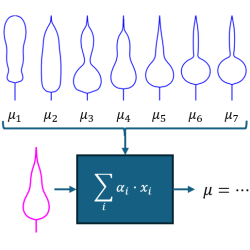

In recent years, the development of artificial intelligence has enabled some disruptive innovations by changing the way research is conducted. More specifically, in computer science, a new way of developing algorithms has emerged, based on machine learning techniques. The core idea is to train the program on many cases to teach the algorithms and then use them with new configurations. In any industrial process, optimizing the operating conditions can be a heavy trial-and-error work. Traditional optimization methods to find them can be very time consuming, so a machine learning approach can be useful to solve such inverse problems. This article shows how to implement an inverse problem solving strategy using COMSOL Multiphysics® and Python machine learning tools through a practical use case: continuous inkjet technology and viscosity deduction by droplet shape detection. In the field of industrial marking, continuous inkjet technology is based on high-speed emission of ink droplets. The shape of the emitted droplets is a combination of ink properties and stimulation operating point and has a direct impact on the printing quality. This article explores the role of viscosity by simulating droplet shape for multiple viscosities using COMSOL Multiphysics® (forward problem) and using machine learning techniques to infer viscosity from droplet shape (inverse problem). This use case illustrates how to set up the main stages of a machine learning inverse problem solving strategy: collecting data, selecting and training a model, testing the model and improving its predictive capabilities. The flexibility of COMSOL Multiphysics® makes it easy to interface with Python machine learning tools to efficiently produce valuable results.