Water Vapor Transmission Through Bagging Materials for Composite Processes

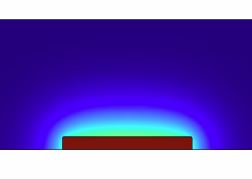

During the manufacturing of CFRP components one of the most critical process steps is the vacuum bagging. In this process several layers of material are draped separately over complex part shapes. The specific properties of each material, which are needed for the process (i. e. breather, release property, air tightness), result into a complex overall behaviour with respect to the process curve. Whilst developing a new generation of vacuum bagging, the necessity to understand and to simulate the new process prior to implementation has been exercised. The following contribution will start with the description of the mass transfer through the bagging material due to the gradient of concentration. Therefore, the theoretical water vapor transmission rate of different bagging materials will be described, compared and related to key features of the manufacturing process. Using a dedicated modelling approach the experimental observations are implemented into COMSOL and the moisture intake or release of an laminate can be predicted. This capability can be used to drive the optimized process layout and conditions such as storage areas, exposition time or sizing of equipment.

Download

- häberle_presentation.pdf - 0.27MB

- häberle_abstract.pdf - 0.01MB