Accelerated Corrosion Test of a Scratched Galvanized Steel Sample

Application ID: 130341

An established method for benchmarking the atmospheric corrosion resistance of materials is the use of accelerated corrosion tests (ACT) performed in climate chambers. The main purpose of the ACTs is to make reliable and fast predictions of the long time behavior. The tests expose samples to cyclic conditions during a few weeks. Elevated temperature, repeated drying and wetting together with salt addition are conditions that typically speed up corrosion and characterize ACTs. The samples can be of all shapes and sizes, in setups targeting crevice or galvanic corrosion, or with inflicted damage.

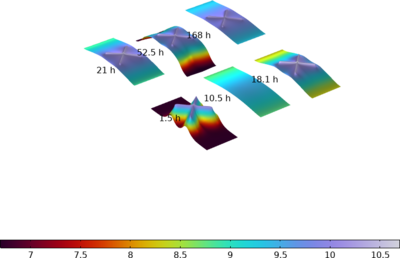

This example studies a galvanized steel sample with crossing scratches that fully penetrate the zinc coating and expose the underlying steel. The corrosion is simulated for a dummy ACT running for 7 days. The model solves for a thin liquid film that covers the sample surface. Local variations in pH, corrosion products, and coating deterioration are shown.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the Battery Design Module, Chemical Reaction Engineering Module, Corrosion Module, Electrochemistry Module, Electrodeposition Module, or Fuel Cell & Electrolyzer Module

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Tabella delle Funzionalità and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.