Development of Quenching Process Recipe Using Simulation by JMatPro and COMSOL

Quenching, a critical process in the heat treatment of railway wheels, significantly affects the mechanical properties and performance of the final product. The development of an optimized quenching process recipe is essential to ensure the durability and safety of railway wheels. This study aims to develop a quenching process recipe using advanced simulation tools, specifically Comsol and JMatPro, to achieve a better understanding and control of the quenching process for railway wheels.

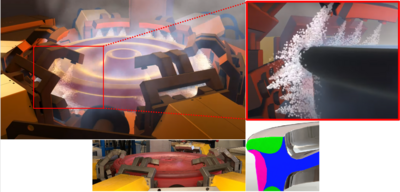

The integration of Comsol and JMatPro offers a comprehensive approach to simulating the quenching process. Comsol Multiphysics provides a robust platform for simulating the temperature profiles and heat transfer dynamics during quenching. By modeling the thermal behavior of railway wheels in real-time, Comsol helps predict the temperature distribution and cooling rates essential for achieving desired mechanical properties. On the other hand, JMatPro specializes in simulating phase transformations and material properties based on the temperature profiles obtained from Comsol. The synergy between these two simulation tools allows for a detailed analysis of the microstructural evolution and phase changes during quenching.

The methodology begins with defining the material properties and initial conditions of the quench sample. The quenching medium, typically water flow or water drops, is characterized in terms of its heat transfer coefficients, flow rates, and temperatures. Comsol is then used to simulate the heat transfer process, generating temperature profiles across the quench sample. These temperature profiles together with data from JMatPro is used to to simulate phase transformations and predict the resultant microstructures and hardness.

A crucial aspect of this study is the validation of simulation results. Experimental quenching tests are conducted to verify the accuracy of the simulated temperature profiles and phase transformations. By comparing the experimental data with simulation results, the model's accuracy is assessed, and necessary adjustments are made to improve the simulation's reliability.

The study also explores the optimization of quenching parameters. Various quenching recipes are simulated to evaluate their impact on the final properties of the sample. Parameters such as quenching medium temperature, flow rate, and quenching duration are varied to identify the optimal conditions that yield the best mechanical properties and minimal residual stresses. The simulations help reduce the number of physical experiments required, thus saving time and resources.

The simulations provide insights into the phase and hardness distribution within the railway wheels during quenching, enabling the identification of critical areas prone to defects. This information is crucial for designing quenching processes that minimize the risk of defects and enhance the overall quality of the railway wheels.

In conclusion, the combination of Comsol and JMatPro for simulating the quenching process of railway wheels offers a powerful tool for optimizing quenching recipes. The detailed simulations provide a deeper understanding of the thermal and microstructural behavior during quenching, leading to improved process control and product quality. The study demonstrates the potential of simulation tools in developing efficient and reliable quenching processes, ultimately contributing to the advancement of railway wheel manufacturing technology.

Download

- comsol-conference-2024-florence.pdf - 0.44MB

- 3_javad_kadkhodapou.pdf - 2.41MB