Modeling of Effect of Particle Size on Macroscopic Behavior of Magnetorheological Elastomers

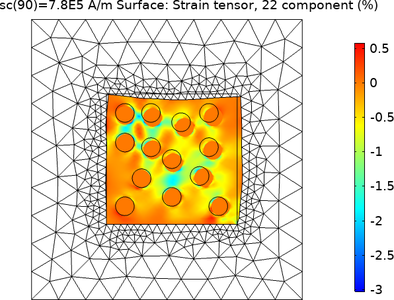

In this work we report on an investigation of the effect of the magnetic particles size on the effective macroscopic behavior of magnetorheological elastomers (MREs). MREs are a class of smart materials known for their tunable deformation. They are composite materials which consist of magnetically permeable particles in a non-magnetic polymeric matrix. When subjected to an external magnetic field, MREs respond by changing their stiffness and damping properties accordingly. Such properties make these materials highly suitable for adaptative applications including vibration dampers and isolators, actuators and sensors. Several factors have been established to significantly influence the so- called magnetorheological effect such as the polymer matrix, particles-volume fraction, properties and size of the magnetic particles. In this study, using finite element simulation we determine the correlation between the latter and the overall behavior of MREs. Based on continuum formulation theory, the constitutive and geometric properties on the microscale are considered in order to predict the composite’s macroscopic behavior by means of a computational homogenization. Using COMSOL Multiphysics® software, the magnetic and mechanical fields were defined and explicitly resolved. For a constant particle-volume fraction (φ=20%) and varying mean particle sizes (Փ=5, 10, 20 and 30 µm), a two-dimensional representative volume element (RVE) was developed, and applying periodic boundary conditions the simulations were performed for isotropic and anisotropic microstructures. The effective magnetic and mechanical properties calculated for isotropic and anisotropic MRE with mean particle size (Փ=10) is as shown in Figs. 1. and 2. Figs. 1 and 2 shows the negative elongation induced in the MRE due to interactions among the filler particles in the direction of the applied magnetic field. From the results (Figs. 3 and 4), it can be seen that the particle size has a significant effect in the mechanical response of the MRE materials. For both isotropic and anisotropic microstructures, the strain effect (ε‾) is observed to decrease with increase in particle sizes, as the particle surface area decreases and the composite becomes less permeable. This agrees with observations made of the scanning electron microscopy (SEM) micrographs of MRE samples with different particle sizes [1], [2]. The resulting larger area of the elastomer reduces the overall reinforcing effect of the mechanically stiffer particles and thus decreased deformational effect in the MRE. Also increasing the particle size, is observed to linearly increase the center to center particle distance for the aligned MRE when the sample is deliberately configured such that the end to end distance between the particles is made equal for all the particle sizes.

Download

- WinnieKiarie_ COMSOL conf 2020_poster.pdf - 0.37MB

- W_Kiarie- Paper.pdf - 0.58MB