Aggiornamenti Metal Processing Module

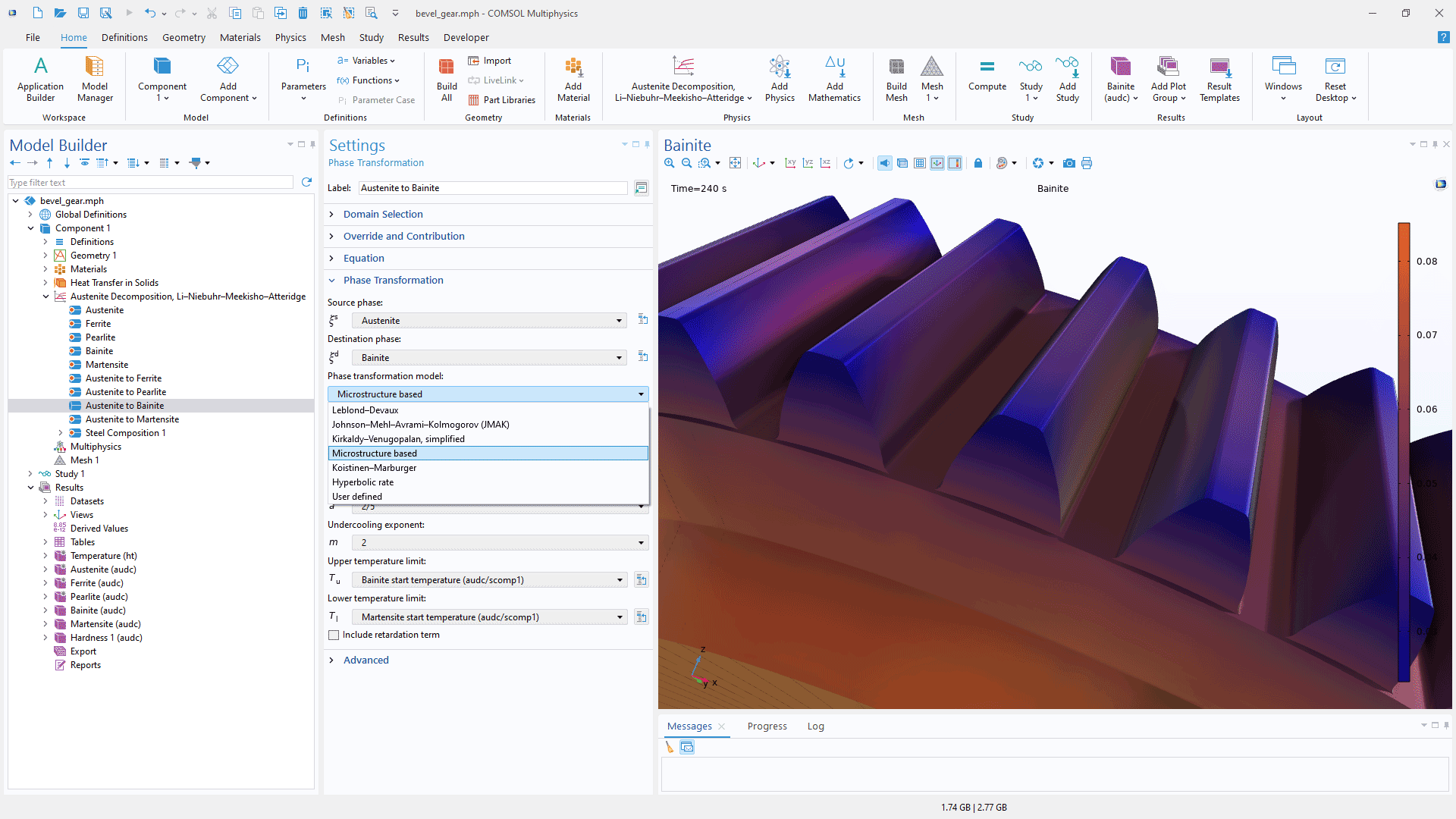

Il modello di trasformazione di fase basato sulla microstruttura

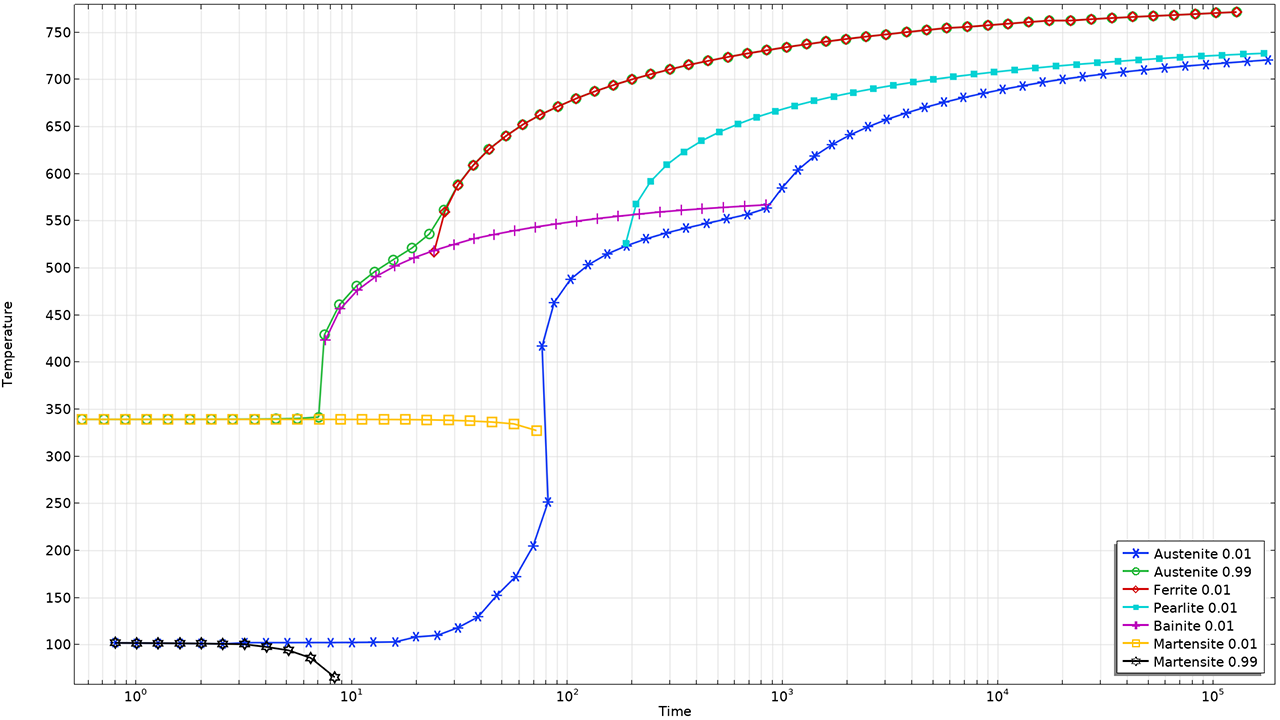

Per le simulazioni della tempra dell'acciaio è disponibile un nuovo modello di trasformazione di fase basato sulla microstruttura. Questo modello di trasformazione elimina la necessità di specificare manualmente il coefficiente di velocità o di adattare il modello ai dati di trasformazione tempo-temperatura (TTT). Si basa sul modello di trasformazione di fase esistente Kirkaldy-Venugopalan, ora denominato modello Kirkaldy-Venugopalan, semplificato. Nel nodo Steel Composition è possibile specificare la composizione chimica, il diagramma Fe-C e la dimensione dei grani di austenite prima di selezionare la formulazione del modello da utilizzare con il modello di trasformazione di fase Microstructure based.

Nuove interfacce per la decomposizione dell'austenite

Sono state aggiunte due nuove interfacce per simulare le trasformazioni di fase durante la tempra dell'acciaio. Le interfacce Austenite Decomposition, Kirkaldy-Venugopalan e Austenite Decomposition, Li-Niebuhr-Meekisho-Atteridge configurano automaticamente le caratteristiche necessarie per le rispettive formulazioni dei modelli di trasformazione di fase Kirkaldy-Venugopalan e Li-Niebuhr-Meekisho-Atteridge.

Miglioramenti all'importazione da JMatPro®

La funzionalità di importazione da JMatPro® include ora la possibilità di utilizzare i dati di trasformazione di fase importati senza predeterminare uno specifico modello di trasformazione di fase. Per molte applicazioni, questo migliora la qualità delle previsioni della composizione di fase.

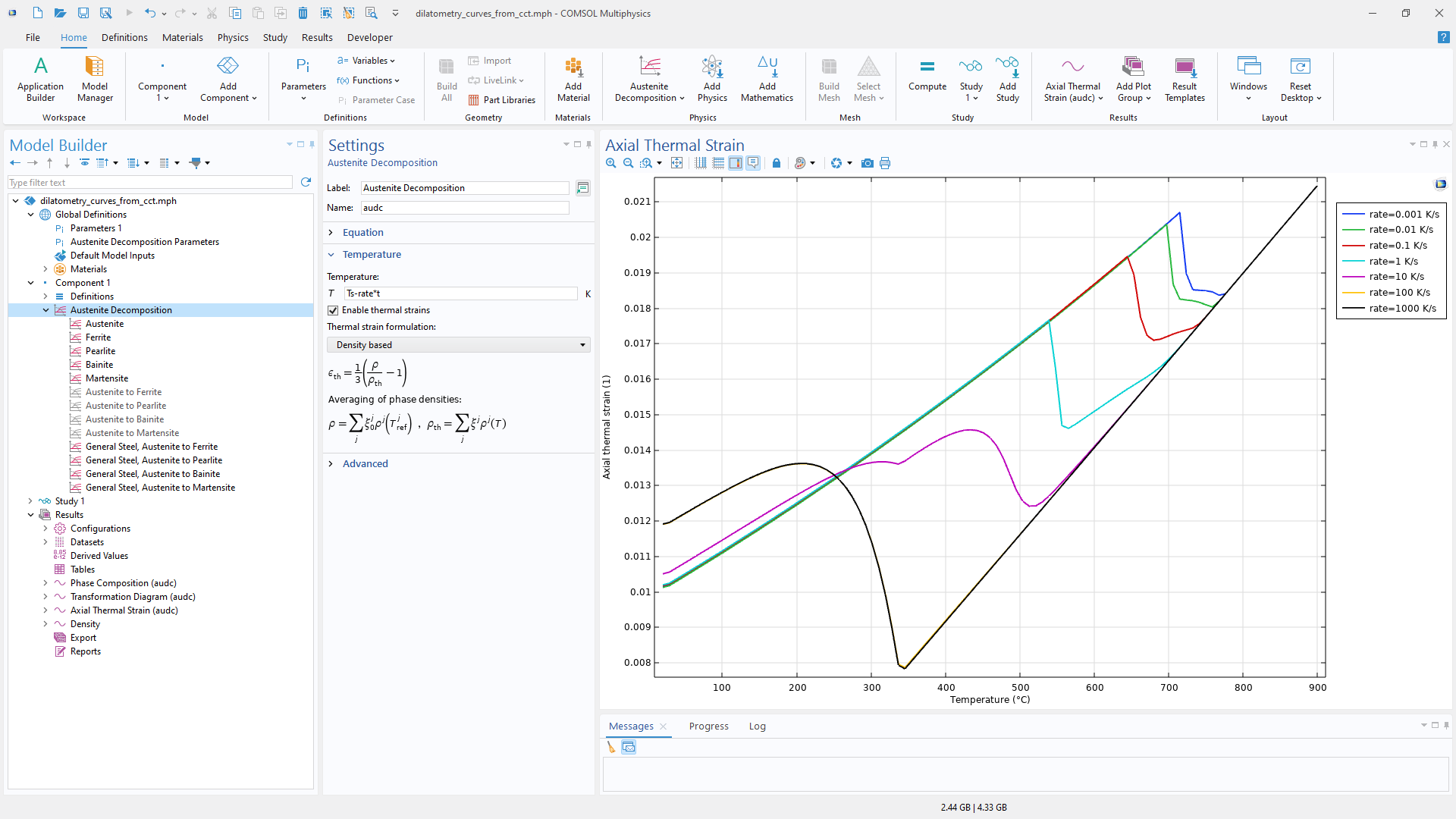

Miglioramento della modellazione della deformazione termica e della deformazione TRIP

Nella versione 6.3, una nuova formulazione Density based consente di basare i calcoli delle deformazioni termiche sulle densità delle diverse fasi in funzione della temperatura. Questa formulazione fornisce un metodo aggiuntivo per catturare, ad esempio, la risposta dilatometrica dell'acciaio che ha subito un cambiamento di temperatura e trasformazioni di fase. Inoltre, i coefficienti TRIP possono essere calcolati utilizzando le densità relative delle fasi coinvolte in una trasformazione di fase.

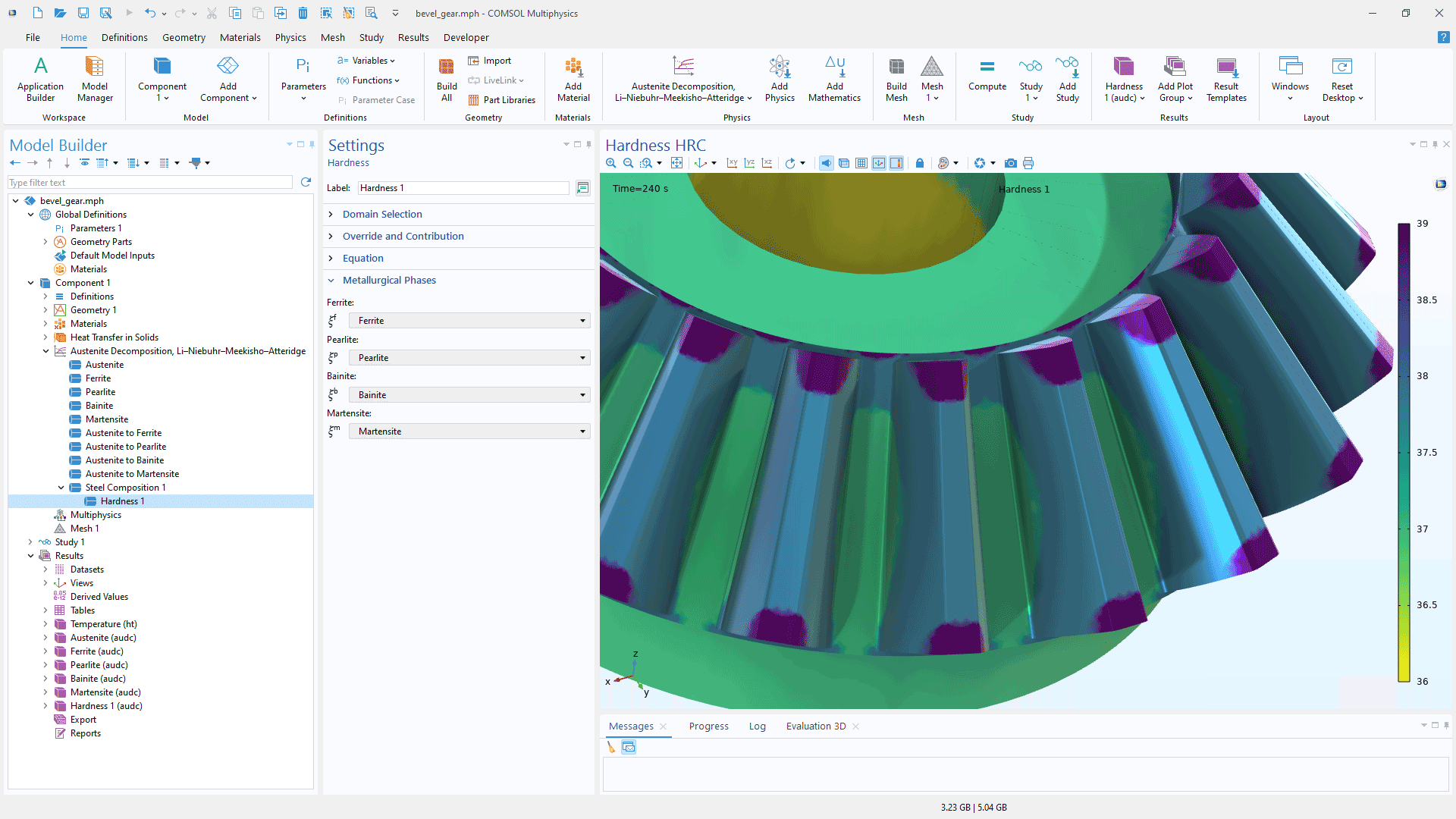

Estensione del calcolo della durezza

La funzione esistente Hardness è stata estesa per includere la funzionalità di calcolo della durezza Rockwell C (HRC) dopo la tempra. Il calcolo della durezza si basa sulla durezza Vickers (HV) calcolata.

Nuovi tutorial

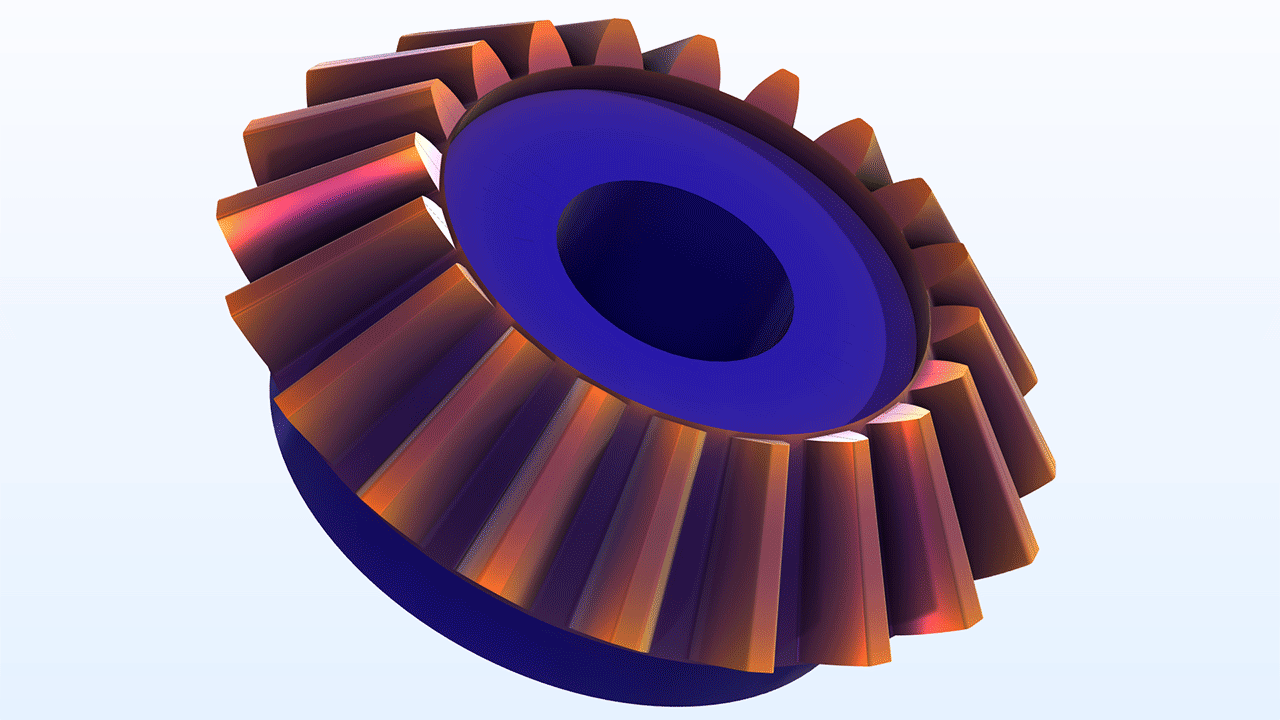

La versione 6.3 di COMSOL Multiphysics® introduce due nuovi tutorial nel Metal Processing Module.

Dilatometry Curves from CCT

Quenching of a Bevel Gear

JMatPro è un marchio registrato di Sente Software Limited.